At Penhall, safety is our #1 priority. So we didn’t hesitate to help when a general contractor called us to help out with an investigation of a potentially hazardous project. He suspected of safety issues in the construction of a high rise hotel in the booming city of Austin, TX.

Penhall assisted with locating structural reinforcement in 49 poured-in-place columns on the first floor of the building, which would go up to 30 stories. The goal of this project was to locate the placement of the vertical pieces of rebar along with the horizontal bands. If columns are not properly poured and installed, it can be detrimental to the integrity of the building as a whole.

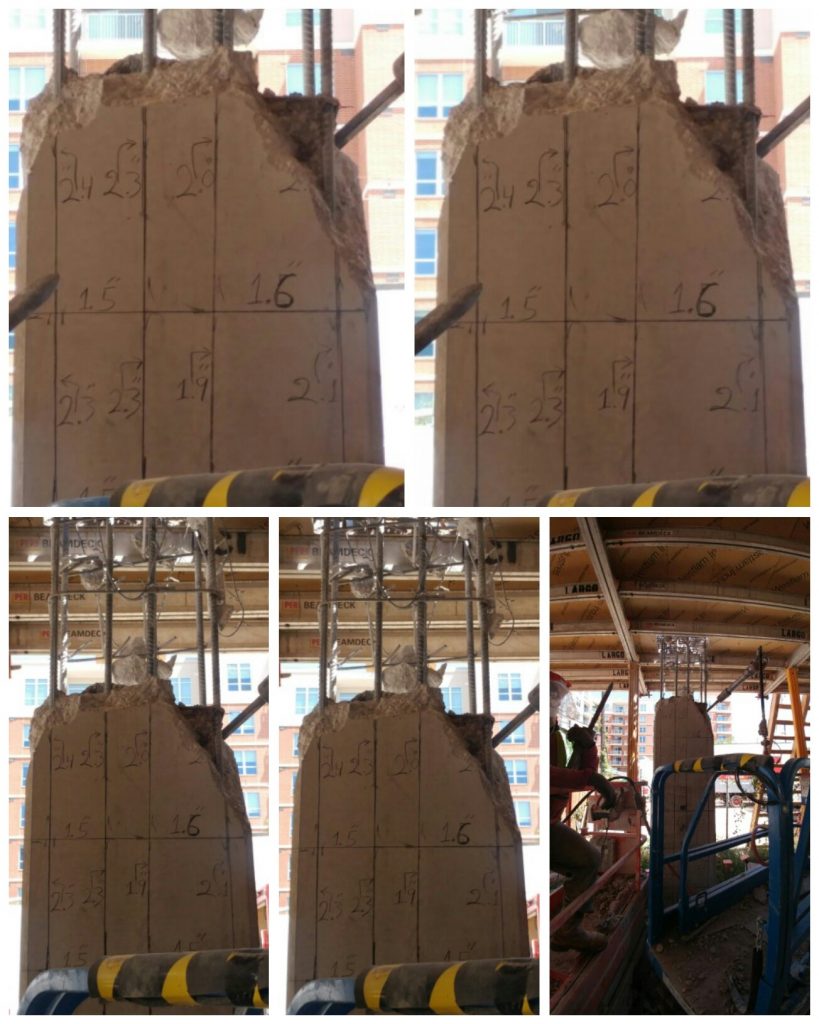

Austin GPR Analysts worked diligently to scan and mark the columns to verify the reinforcements. The results, as you can see in the image sequence above, were very telling. 48 of the 49 columns had improper spacing of the rebar. In other words, they lacked the structural integrity to withstand the weight of a multilevel building.

Following the analysts’ findings, the general contractors made the decision to fix all 48 columns. This allowed the general contractor to resume the project and to complete it safely. Penhall walked away from this project knowing that our work minimized the threat of a potentially hazardous situation.

For further questions or to receive a quote:

Call or email us at:

844-211-5300

Or visit our website: