PENHALL'S SURFACE PREPARATION SERVICES ARE SUITABLE FOR EVEN THE MOST CHALLENGING PROJECTS.

Penhall is committed to helping you produce surfaces that meet the everyday demands of professional flooring, whether in the industrial, commercial or public sector. Choose Penhall and discover solutions that provide the features you need for your specific circumstances.

SURFACE COATING REMOVAL

FLOOR SCRAPING

Remove old or worn-out floor coverings such as ceramic tile, linoleum, laminate, vinyl, carpet, glued wood, and roofing materials. Penhall Company offers a complete range of scraping services for the removal of bonded floor coverings.

FLOOR SHAVING

Shaving is great for removing anything that cannot be removed by other means. A drum with a diamond blade is placed inside the drum body and rotates at a very high speed, grinding away the surface. The dust and dirt generated by the shaver is transferred to a dust collector, making the process virtually dust-free during operation.

THIN COATINGS FROM HARD FLOORS

THIN COATINGS FROM SOFT FLOORS

THICK COATINGS FROM HARD FLOORS

THIN COATINGS FROM SOFT FLOORS

GLUED SOFT COVERINGS

GLUED HARD COVERINGS

SURFACE PREPARATION

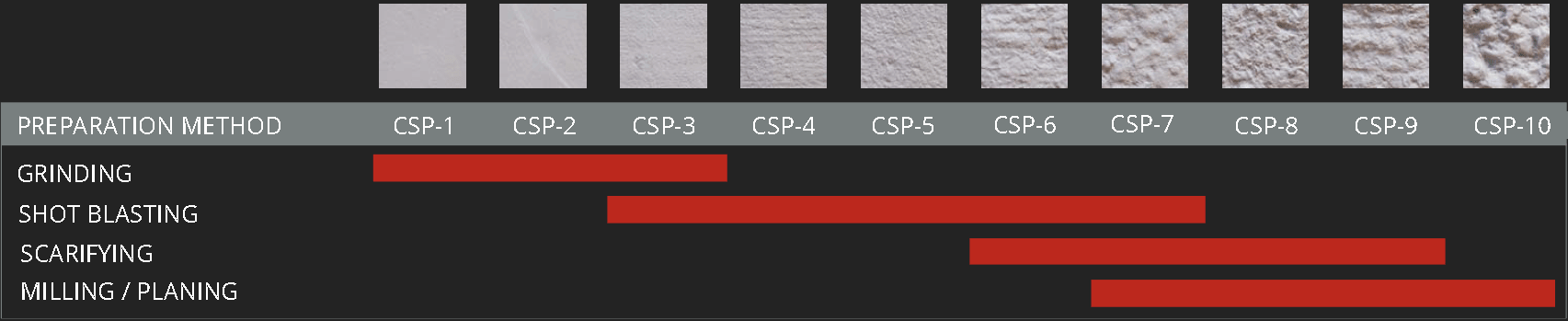

GRINDING

Concrete Grinding Applications range from preparation for and the removal of coatings, surface flattening, honing and polishing of concrete and natural stone surfaces. Concrete Grinding leaves a Concrete Surface Profile raning (CSP) from 1 to 3.

SHOT BLASTING

Shot blasting is used to clean and retexture concrete surfaces. Shot blasting is a process of blasting a steel abrasive material at the surface. After the media hits the surface it is recycled and dust is collected to a dedicated dust collector. This makes the process almost dust free in operation and leaves the surface at a CSP ranging from 3 to 7.

SCARIFYING

Scarifiers, also known as surface planers or milling machines, are used to cut or scar the surface of concrete with the use of tungsten carbide cutting tools that rotate around a drum. Scarifiers remove concrete quickly and aggressively, leaving a CSP ranging from 6 to 9.

CSP PROFILES

Proper surface preparation of an existing concrete floor is essential for achieving a successfully completed project. Resurfacer, self leveler, sealer, coating or stain should only be used after proper surface preparation. Preparing the existing concrete surface properly will save you time and cost. The International Concrete Repair Institute (ICRI) has defined ten classifications for proper surface preparation, each profile carries a CSP Number ranging from 1 (nearly flat) through 10 (very rough).

SURFACE FINISHING

Finished concrete is a very cost effective solution and environmentally friendly solution. When a concrete floor is cast the strongest material, the stone aggregate, settles just below the surface leaving mainly cement at the upper surface. Once surface coatings are removed and the proper surface preparation is in place concrete can be finished to achieve the desired results. The final result is a highly durable, low-maintenance flooring, eco-friendly solution.

Polished Concrete

Polished concrete floors are popular in industrial and commercial facilities due to their high durability, low life cycle cost, slip resistance and aesthetics.

BUSH HAMMERED CONCRETE

Bush-hammering concrete is a process that enables you to achieve a similar effect as natural cut stone. Bush-hammered concrete is ideal for swimming pool areas, or for anti-skid surfaces in pedestrian areas.

GROOVED CONCRETE

Concrete grooving is the process of creating patterns along the surface of concrete to prevent slipping. A wide range of groove patterns can be obtained using different configurations of blades and drums.

CONTACT US TODAY

TESTIMONIALS

CLICK TO VIEW SERVICES