Four Reasons Why Concrete Scanning is Essential for Your Project

In construction and renovation, hitting an unforeseen obstacle buried within concrete isn’t just an inconvenience. It can be a critical failure that can jeopardize safety, finances, and the entire project timeline. This is where concrete scanning, particularly utilizing advanced Ground Penetrating Radar (GPR) technology, becomes an important pre-construction measure.

What Is Concrete Scanning?

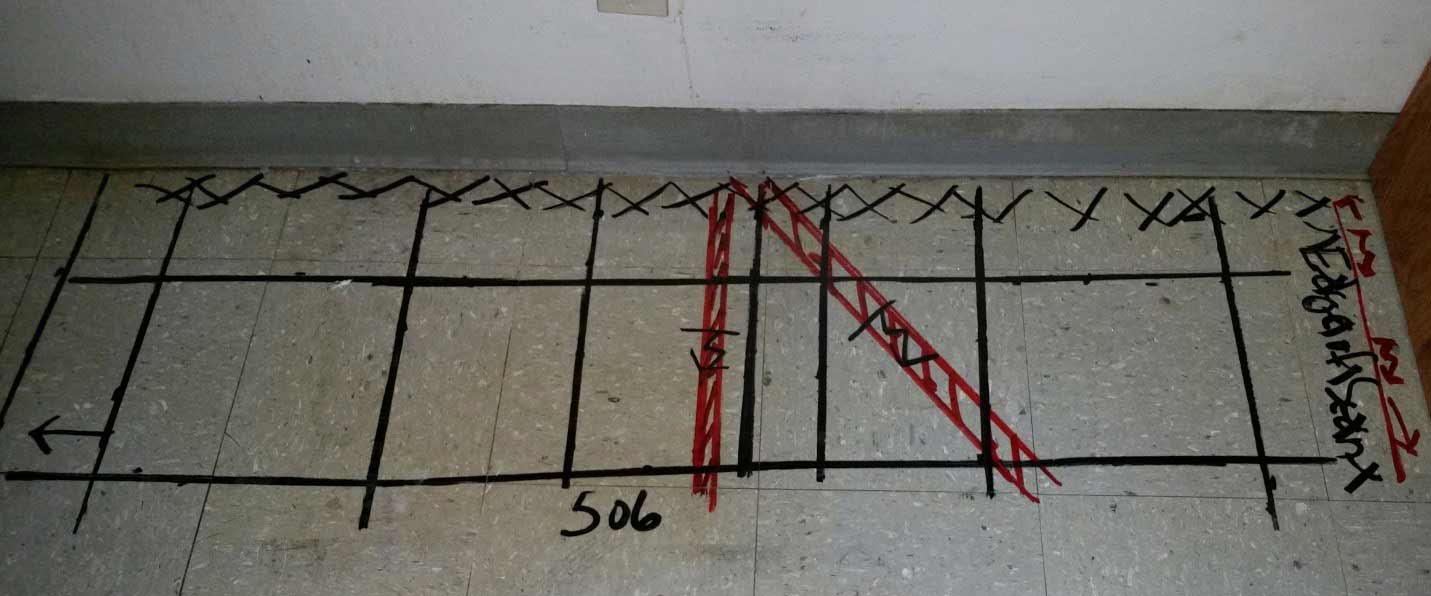

Concrete scanning is a non-destructive evaluation (NDE) method that uses radar pulses to create a detailed, real-time image of what lies beneath the concrete surface. Before you drill, saw, or core, a GPR scan reveals hidden hazards like:

- Rebar and wire mesh

- Post-tension cables

- Electrical conduits and live wires

- Water, gas, or sewer pipes

- Voids, delamination, and subsurface anomalies

Why Is Concrete Scanning Required?

Concrete scanning is an important step in the construction process that helps facilitate enhanced safety, project efficiency and time savings, cost savings and accuracy. While some might view scanning as an added step, the reality is that it offers a massive return on investment. Let’s look into each of these reasons why concrete scanning is essential.

Enhanced Safety

Safety is a primary reason for concrete scanning. When workers cut into concrete without prior knowledge, they are quite literally playing a guessing game with potentially catastrophic consequences.

- The Danger of Electrocution: Striking a live electrical conduit or cable can result in severe injury or death for the worker and can cause a power outage, impacting the entire facility.

- The Blowout Hazard of Post-Tension Cables: Post-tension (PT) cables are high-strength steel strands anchored and tensioned within concrete slabs to provide structural support. If a PT cable is cut, the immense stored energy can be released in a violent blowout, causing the cable to snap, whip, or expand out of the concrete, severely injuring anyone nearby and compromising the structural integrity of the slab.

- Avoiding Utility Breaches: Cutting into gas, water, or chemical lines can lead to explosions, flooding, or exposure to hazardous materials. Scanning proactively identifies these high-risk areas, allowing work to be performed safely or the design to be modified to avoid them.

Project Efficiency and Time Savings

Time is valuable on any construction site, and striking a subsurface object is the fastest way to bring a project to a screeching halt.

If a contractor hits a critical line or structural element, the project immediately shifts from construction to crisis management. This introduces significant, unpredictable downtime for:

- Assessing the Damage: Stopping all work in the affected area and waiting for a structural engineer or utility expert to inspect the damage.

- Repair and Rerouting: Spending hours or days repairing the conduit, patching the hole, or determining a new path for the intended cut or core.

- Waiting for Approvals: Obtaining revised permits or approvals for structural changes.

By investing a small amount of time in GPR scanning up front, project managers can ensure that every single cut, core, or trench proceeds smoothly and without incident, keeping the entire project on its scheduled trajectory.

Significant Cost Savings

How much does scanning cost? While concrete scanning services represent an initial investment, they deliver profound cost savings by preventing exponentially more expensive problems.

Consider the financial implications of a single strike:

- Expensive Repairs: Structural repairs, especially those involving PT cables, are complex and costly, requiring specialized labor and materials. Repairing a severed electrical conduit or ruptured pipe can involve plumbing, electrical, and concrete patching specialists.

- Delay Costs (Liquidated Damages): When projects are delayed, contractors may face financial penalties known as liquidated damages. Avoiding a delay saves money not just in repair costs but in penalties and extended overhead (equipment rental, supervisory labor).

- Injury and Liability: The costs associated with an on-site injury—medical bills, potential lawsuits, and increased insurance premiums—far outweigh the cost of a pre-work scan.

Scanning shifts the budget from “unforeseen incident repair” to “proactive risk mitigation,” offering a clear financial advantage.

Accuracy and Structural Integrity

One of the most significant benefits of concrete scanning is accuracy. And ultimately, concrete scanning provides the accuracy needed to protect the structural integrity of the building.

The ability to look inside the slab allows analysts to mark the precise location of structural supports like rebar mats and post-tension systems. This enables a contractor to:

- Confirm Clearances: Ensure that the proposed location for a new opening, anchor, or penetration is entirely free of critical elements before making the first cut.

- Maintain Structural Soundness: Avoid cutting vital reinforcing steel that ensures the slab’s load-bearing capacity. If too much rebar is cut, it can lead to long-term cracking, deflection, and catastrophic structural failure.

- Optimize Placement: When multiple hazards exist, GPR allows the project team to choose the safest, most structurally optimal location for coring or cutting, ensuring the new installation integrates flawlessly with the existing structure.

Concrete scanning is about guiding work with precision and confidence, not just about avoiding hazards.

In modern construction, knowledge is power, and when dealing with concrete, that power is delivered by GPR. By making concrete scanning a standard operating procedure, construction teams move beyond guesswork. They are able to guarantee the safety of their personnel, preserve the structural integrity of the building, and keep their projects on time and budget.