What is Pre-Task Planning (PTP)?

Pre-Task Planning (PTP) is a proactive safety practice designed to identify potential hazards and mitigate risks before work begins. It’s an essential process for improving safety, ensuring compliance, and enhancing productivity on any construction site.

How Does PTP Work?

PTP involves assessing specific tasks and potential risks to create a comprehensive plan that prioritizes safety management. The process is broken down into three key steps:

1. Before the start of any task or job, the supervisor/employee (or whoever is in charge of the project) needs to identify three main things:

- The task(s) that need to be completed that day.

- The potential hazards that could be involved in the completion of those tasks.

- The corrective measures that will be put in place to avoid/mitigate the identified hazards.

For example, let’s say the project task is to flat saw a six inch thick slab of concrete. One of the first things that need to be done is for the supervisor or person in charge of the project, to walk the site with the customer (and walk the site solo) to identify potential hazards, such as:

- Underground services: Typically when cutting concrete, Penhall Company Concrete Cutting Professionals are continually exposed to gas lines, water lines or electrical lines that could be under the concrete or asphalt or embedded in the concrete.

- Traffic: If the work is conducted on a street or near an area where people are driving, the crew needs to determine what kind of barriers or work area delineations need to be put in place to protect the safety of the workers and drivers.

- Pedestrians: Work that is conducted in public areas can expose both workers and bystanders to harm (e.g. flying objects, slip/trip hazards, exhaust fumes, etc.).

2. Once all the potential hazards have been identified, measures must be put in place to control the hazards.

For example:

- Underground services: Call 511 (number for dig alert) and have someone come out and identify what’s underground and where it’s at.

- Traffic: Put a truck between worker and traffic; delineate the work area using cones, etc.

- Pedestrians: Use spotters to keep unauthorized people out of the work area; vacuum slurry water immediately; etc.

3. Pre-Task Planning is also applied to the tools and equipment used on the job and the personal protective equipment (PPE) that the crew wears and uses.

It’s important to remember that PTP should also be applied to tools, machinery, and personal protection equipment (PPE). Identifying the potential hazards related to equipment and verifying that corrective measures are in place is an essential part of ensuring safety, productivity, and morale. This proactive safety approach helps mitigate potential risks and enhance compliance with safety standards.

For instance, if a blade is used, one of the corrective measures to prevent someone getting cut would be to use a blade guard and to inspect the structural integrity of the blade guard.

In addition, if a situation changes while the job is underway, all workers must take a “time-out and stop work,” to conduct a new PTP to evaluate the changing hazards and to assess whether the existing corrective measures will sufficiently mitigate the hazards, or if new corrective measures need to be implemented. This ensures that the job hazard analysis (JHA) remains relevant and effective.

Here are a few examples of questions that operators should ask themselves during their PTP process to validate that the equipment is in good condition and functioning properly before it gets to a customer’s location or job site.

Flat Saw:

- Does the engine have oil?

- What is the hydra drive fluid level? Is that sufficient?

- Does it lift and lower smoothly?

- Are the blade guards in place?

Small Gas Powered Equipment:

- Is the oil level sufficient?

- Is the On/Off switch working properly?

- Is the battery and connections functioning properly?

Hydra Pack:

- Is the engine oil level ok?

- Are the remote and override switches ok?

- Are there any leaks?

- Is the GPM flow adjusted to match the tool?

- Is the PSI adjusted to match the tool?

Core Drilling:

- Is the carriage tight on the mast?

- Does the carriage have all the handles and rack gear? Are they ok?

- Are the base adjusters in place?

Trailers:

- Is the tire pressure adequate?

- Are the tires in good condition? What about the rims?

- Do the springs have defects?

- Is the pintle eye in good condition?

- Is the ball/pintle hitch attached and locked?

- Is the coupler in place?

- Are the lights working?

Wall Saws:

- Is the carriage tight on the track?

- Are the output/blade shaft threads ok?

- Are the factory guards in place and ok?

- Are the blade flanges and keyway ok?

- What is the condition of the hoses? Is it sufficient?

- What is the condition of the electric cables and plugs?

- Are there any cracked swivels?

Hand Saw/Chop Saw:

- Are the factory blade guards in place?

- Is the output/blade shaft ok?

- Is the trigger clean and operating freely?

Diamond Tools:

- Is the proper blade guard installed?

- Is the blade/core free of cracks?

- Is the blade flat and positioned to run at the selected RPM?

- Does the saw/shaft speed match the blade specified RPM?

- Is the blade rotation correct?

- Is the core bit RPM set to match the diameter and application?

4. Who is responsible for Pre-Task Planning?

Effective task planning involves all team members to ensure comprehensive safety management.

If the job is a contract job or a job that is managed by a supervisor, the supervisor will create his/her hazards list and corrective measures. Then, during the morning “Pre-Task Planning” meeting, the supervisor will review the day's plan, hazards and corrective measures and then seek input from the crew and ask if there’s anything on the PTP that they think has been left out or overlooked or needs to be added. This gives the employees the opportunity to contribute to the planning of the project that they will be working on.

However, if an hourly service employee is working independently on a job, they will create their own PTP documents.

Benefits of Pre-Task Planning

Pre-Task Planning offers numerous benefits beyond just keeping people safe. It significantly enhances project efficiency and overall success. By taking the time to plan ahead, teams can identify potential bottlenecks and address them proactively. This leads to smoother operations and fewer unexpected delays.

Moreover, PTP fosters better project coordination. When all team members are involved in the planning process, it ensures everyone is on the same page regarding tasks, potential risks, and mitigation strategies. This open communication builds a stronger, more cohesive team that can work together more effectively.

PRE-TASK PLANNER

Physical Hazards

- Falling Objects

- Sharp Objects

- Walking and Working Surfaces

- Impact From or By

- Work Over or Near Water

- Heavy Lifting

- High Noise

- Hot Surfaces

Task Specific Hazards

- Fall from Height 6 Ft.

- Scaffolding

- Climbing Ladders

- Electrical Energy

- Excavations and Trenching

- Confined Space Entry

- Slips, Trips and Falls

- Moving Machinery

- Hand Power Tools

- Raising and Lowering Materials

- Floor or Wall Opening

- Traffic

- Pinch or Crush Points

- Machinery Operations

Traffic and Pedestrian Control

- Signage and Barricades

- Flag Person

- Arrow Boards

- Delineations

- Traffic Control Plan

Fall Protection and Prevention

- Full Body Harness

- Fall Plan

- Vertical Life Line

- Guard Rails

- Retractable Lanyards

- Lanyards

- Hole Covers and Barricades

- Control Access Zones

Excavation and Trenches

- Competent Person

- Escape Ladder

- Barricades and Plating

- Shoring, Sloping and Benching

- Signage and Cones

Confined Space Entry

- Permits Completed

- Crew Trained

- Ventilation

- Atmosphere Monitored

- Rescue Plan

Emergency and Medical

- First Aid Kit

- Call 911

- Call Dispatch

Health and Housekeeping

- Trash and Debris Contained

- Liquids Available

- Respirator Clean

- Heat Stress

Preparing for the Unexpected

While thorough Pre-Task Planning significantly reduces risks, it's impossible to predict every scenario. That's why it's crucial to have backup plans in place. Consider potential delays or issues such as adverse weather conditions, equipment breakdowns, or absent employees.

By being proactive and having contingency plans, you can reduce stress and resume progress quickly if unexpected issues arise. This level of preparedness not only enhances safety but also demonstrates professionalism and commitment to project success.

Remember, the goal of Pre-Task Planning isn't just to complete paperwork—it's to create a safer, more efficient work environment for everyone involved. By consistently applying these principles and remaining vigilant, we can all contribute to a culture of safety in the construction industry.

Stay safe!

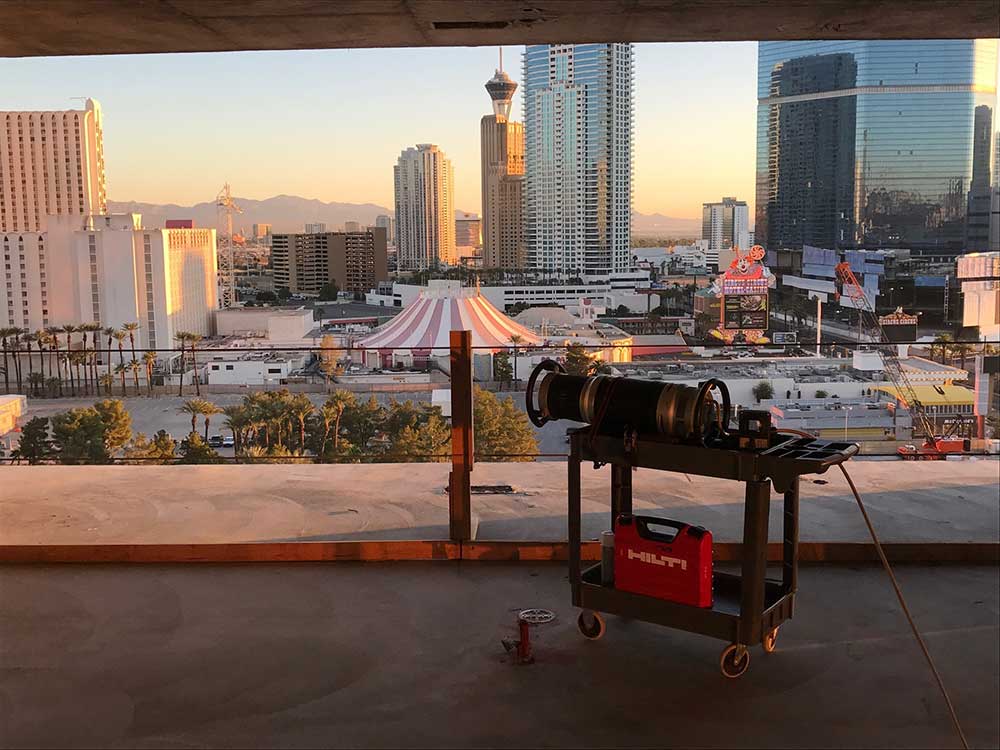

This system worked in a very particular way. The truck had a camera and a microphone that allowed the analysts and the driver to communicate. Depending on the required scan areas, the driver moved the boom lift accordingly. The entire scan job was done using this unique mobile system.

This system worked in a very particular way. The truck had a camera and a microphone that allowed the analysts and the driver to communicate. Depending on the required scan areas, the driver moved the boom lift accordingly. The entire scan job was done using this unique mobile system.