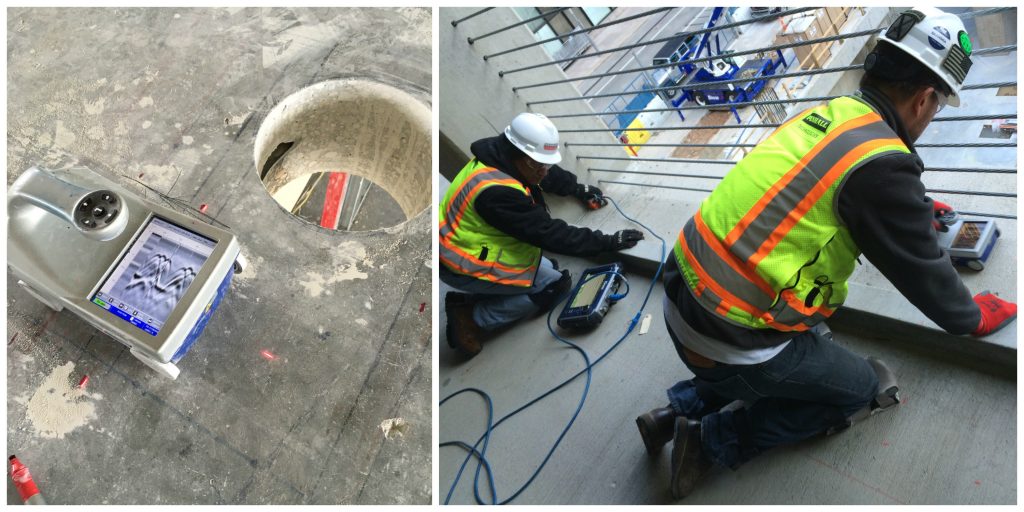

When looking for a utility line locator to locate anything from underground water lines, gas lines, electrical/power lines to underground storage tanks, it is a good idea to know the capabilities and limitations of the technologies used in those detection services.

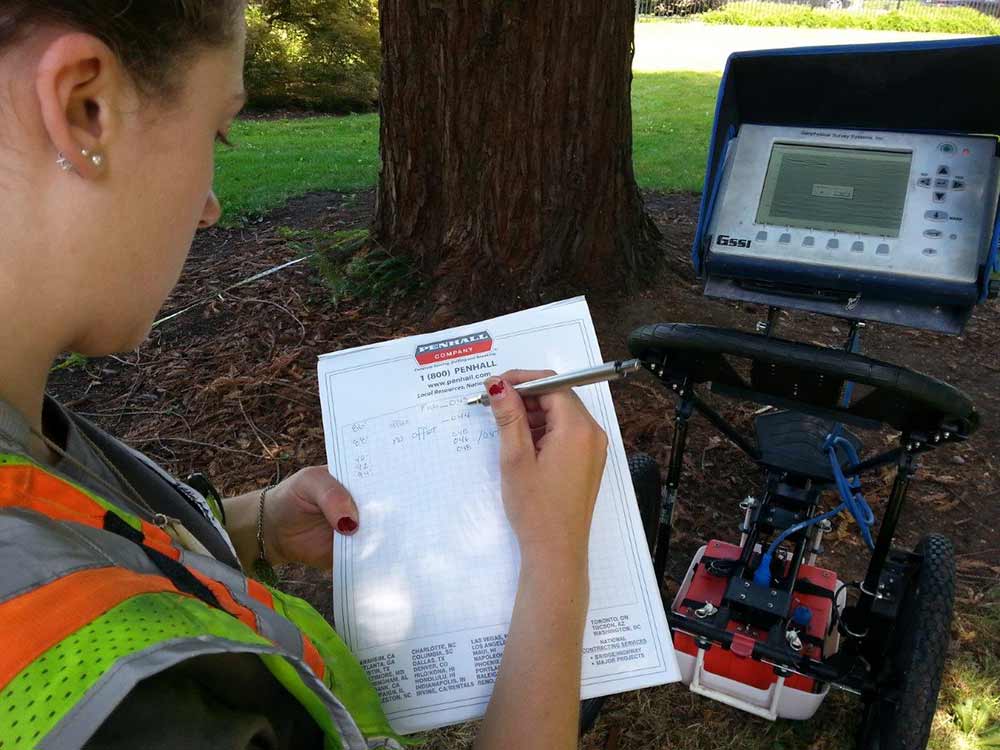

Penhall Technologies uses both GPR (ground penetrating radar) and Electromagnetic Detection. Here, we will dive deep into GPR and what factors affect the capabilities and limitations of this technology.

1. Weather Conditions

Because moisture raises the conductivity of the ground, especially clay soil and silt, deep snow and rain can be a factor in utility locating. Once the radar touches any ground holding moisture, it bounces right back. This makes it tough to read anything past that water table. Therefore, the winter months are not ideal to do any type of locating.

2. Soil Conditions in Area

Now that you know that moisture plays a role in messing with GPR data, the types of soil conditions that become a factor are those that hold the moisture the most, like clay soil or silt. Interestingly enough, sandy soils, although typically near bodies of water, are more ideal to scan over than clay soils.

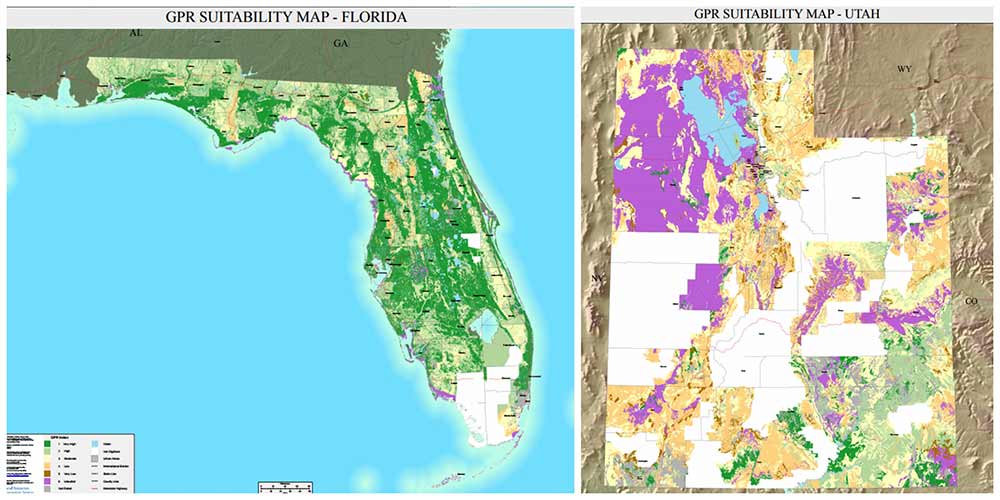

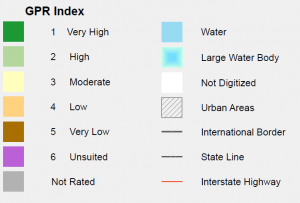

Each area throughout the US have certain types of soils that are native to the area, so it is a good idea to check what the soil conditions are in your area before moving forward. Here is a helpful link to find out the suitability of GPR in your state and area.

Here is a side by side comparison between states, Florida and Utah. Utah has more clay soil vs Florida with more sandy soil.

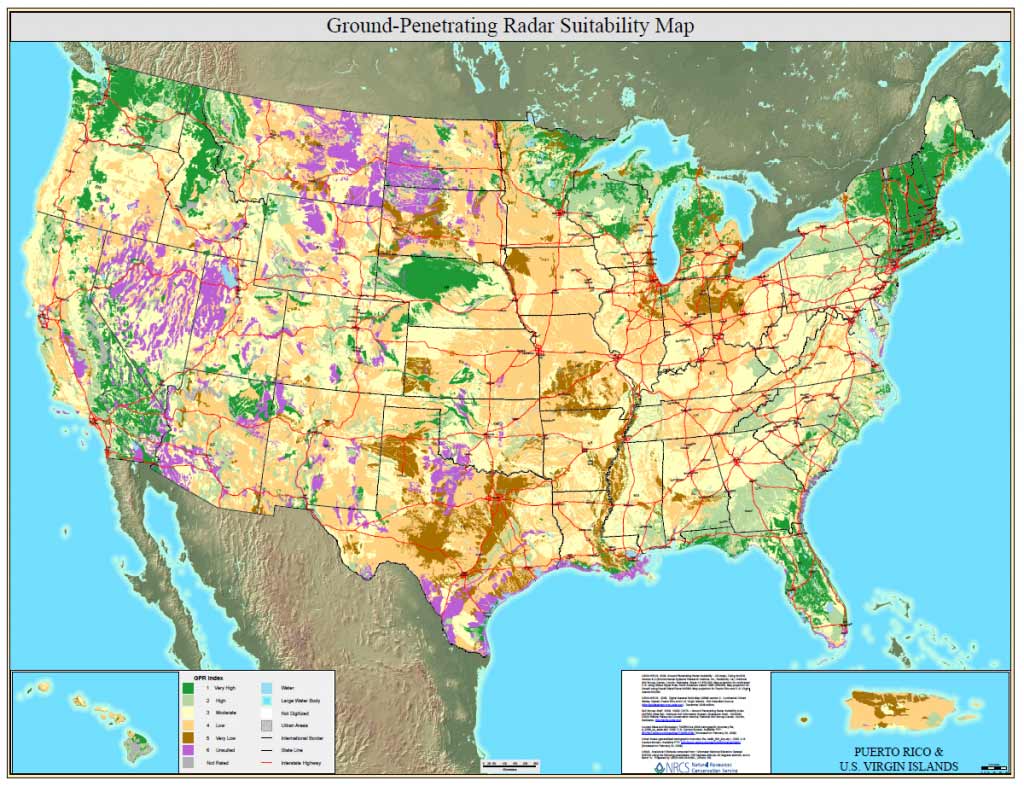

3. Surface Area – Clearance and Obstacles

The surface being scanned becomes a factor for GPR data when the terrain is rough enough to cause the equipment to separate from the surface more than 2 to 3 inches. The quality of the data when this happens is then compromised. Ideally, the surface needs to be reasonably flat with a good amount of clearance. Obstacles, like trees and bushes, are mainly factors that can cause a delay in the time.

4. Limitations of Technology with Certain Materials

GPR is highly successful for locating many types of objects. That said, there are certain materials that are much more conductive and easily located than others. Metal, for example, is highly conductive, and PVC or plastic has no conductivity, which makes it more challenging to locate. PVC and other non-metallic objects do not show a signal, but rather the signal can show something inside the pipe, like air or water. The size of the PVC does impede the ability for the radar to read if it is smaller, like a 1” line. This is because the radar used is for utility locating is typically one that is too large to “see” a line that is that small (See “Radar Frequency – Antenna” below for more info on this). Fisher wire/tape can be used to aide in identification in these cases.

Another factor that can impede on the GPR data is when scanning over a concrete slab with wire mesh. Because the wire mesh is metallic and the frequency of the antenna used is low and large, it inhibits the signal from penetrating clearly.

5. Radar Frequency – Antenna

The higher the frequency, the smaller the radar, so high frequencies are best for tighter and shallower areas. The lower the frequency, the larger the radar, so these frequencies are best for deeper penetration and larger objects like pipes. In utility locating, the antennas with lower frequencies are best.

The limitation of the antenna becomes a factor mainly when any of the above factors come into play. Also, another factor to consider is when the depth of an object needing to be located surpasses the limit of the antenna’s radar. The strongest antenna commonly used throughout Penhall Technologies can scan to a max depth of 9 feet. We find that most utilities can be found within this range. Antennas that can scan a deeper depth may be available. Please contact us directly if a deeper locate is necessary for your project.

So, there you have it. We hope that this helps to clarify any questions regarding factors that affect GPR in utility locating. When in need of underground utility locating services, and you’re not quite sure about the capabilities of GPR on any given project, the best approach would be to contact us directly. To best serve our customers, we will always be upfront and honest about the capabilities and limitations of our technologies. We can offer any alternative approaches that we may have.

Now, there is a push button – as you’re drilling and you come to an obstruction, you don’t shut off the machine, you can just switch speeds automatically. This has greatly improved the efficiency of operators because every second on the job counts, and those lost seconds of manually switching speeds add up.

Now, there is a push button – as you’re drilling and you come to an obstruction, you don’t shut off the machine, you can just switch speeds automatically. This has greatly improved the efficiency of operators because every second on the job counts, and those lost seconds of manually switching speeds add up. Eventually auto feed emerged where you could crank it and the unit would travel by itself. However, if the operator wanted it to move another direction, they would have to manually crank the unit again.

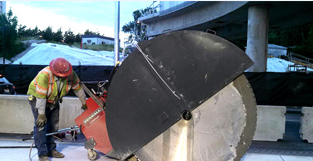

Eventually auto feed emerged where you could crank it and the unit would travel by itself. However, if the operator wanted it to move another direction, they would have to manually crank the unit again. Currently, the flat saw machine is drastically different. Now an operator can use 18” or 20” blades to start and cut 6” deep in one pass. The current flat saws also have a push button starter, 3 speed transmission, hydraulic drive, and diesel engine. Place a car body on them and you could drive that thing!

Currently, the flat saw machine is drastically different. Now an operator can use 18” or 20” blades to start and cut 6” deep in one pass. The current flat saws also have a push button starter, 3 speed transmission, hydraulic drive, and diesel engine. Place a car body on them and you could drive that thing!

Thorough job site set-up

Thorough job site set-up